Product Categories

Hot Products

-

Product Name: Electric Flat...

-

Product Name: Lifting...

-

Product Name: Type A 5t-800t double-beam...

-

Product Name: Gantry Crane for Railway...

-

Product Name: FEM/DIN Double Girder...

Project Case

I. basic information

1. The newly purchased Weihua crane gantry crane platform of

your company shall be installed on the crane track at the site of the

production area with the total length of m.

2. Structure and technical performance parameters of Weihua

crane:

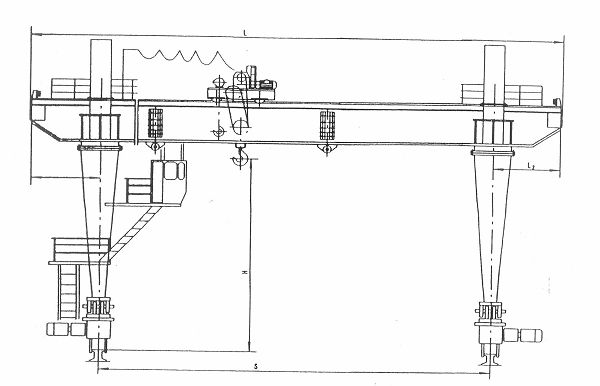

(1) crane structure: double beam gantry crane is composed of the

main beam and legs, the lower beam gantry frame, crane trolley, driver's cab,

mechanical and electrical equipment, etc., the overall structure of the machine

is shown in the figure (see weihua crane plan for details).

(2) technical performance parameters of the crane, as shown

in the weihua crane plan.

Ii. Process equipment and hoisting method of Weihua crane gantry

crane

1. Hoisting process equipment and inspection instruments

According to the gantry crane on the piece weight and leg flange

height, crane installation, weihua crane program USES the crane as the main

hoisting equipment, crane lifting weight respectively two forklift lifting

weight t1, t, t trailer 1, test instruments, such as a theodolite, level, box

type level, megohmmeter, steel tape, square (2 above), vernier caliper, feeler,

steel wire, a heavy hammer, micrometer, dial indicator, etc

2. Hoisting method

According to the site conditions and hoisting requirements of

the crane, weihua crane generally adopts the following steps for installation:

The ground is piecewise manufactured main beam connection group

pair;

The driving trolley is connected with the lower transverse;

Install fixed lower beams on rails• • • • • •

Iii. Sequence diagram of installation and construction

technology of Weihua crane gantry crane (the construction technology adopted

varies according to the specific type of gantry crane)

Iv. Installation technology of Weihua crane

(1) preparation before crane installation

(2) crane bridge installatio

Technical requirements for the installation of Weihua crane gantry cranes

|

number |

project |

Allowable deviation (㎜) |

|

1 |

1. Span S1 and S2 of the crane measured by wheels Span relative difference │ S1, S2 │ 2. Crane span S3 and S4 measured from the bridge frame Span relative difference │ S3, S4 │ |

1、S≤26m:△S=8 │S1-S2│≤8 S>26m: △S=10 │S1-S2│≤10 2、S≤26m:△S=4 │S3-S4│≤4 S>26m: △S=6 │S3-S4│≤6 |

|

2 |

Camber of the main girder after erection (measured on the cover plate of the rail beam) |

F=(0.9/1000-1.4/1000)S FO=(0.9/350-1.4/1000)So |

|

3 |

Horizontal side bending of main beam (measured on the upper cover plate of rail bearing beam) |

National standard (latest) |

|

4 |

│D1-D2│Bridge diagonal deviation │ D1, D2 │ |

National standard (latest) |

|

5 |

Trolley gauge deviation |

National standard (latest) |

|

6 |

The perpendicularity of the supporting leg |

National standard (latest) |

|

7 |

Bending of main compression bars between bridge joints |

National standard (latest) |

|

8 |

Car track height difference (in the same section) |

National standard (latest) |

|

9 |

The displacement deviation of the center line of the track from the design center line of the rail bearing beam |

National standard (latest) |

|

10 |

The vertical inclination of a bridge frame |

National standard (latest) |

|

11 |

The difference between the car tracks |

National standard (latest) |

|

12 |

Lateral dislocation of car track joint |

National standard (latest) |

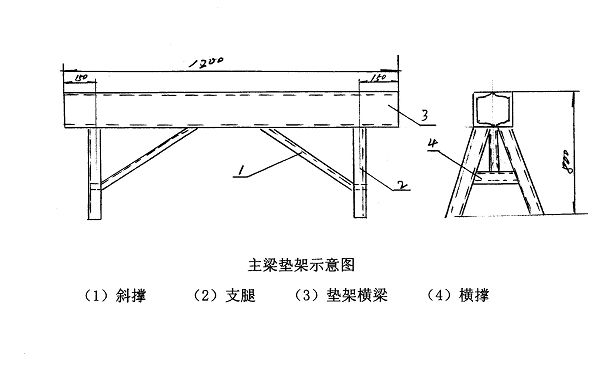

(3) main girder pad frame production

Pad rack material selection Q235 is easy, pad rack should have

enough steel.As shown in figure

(4) hoisting of the lower beam.

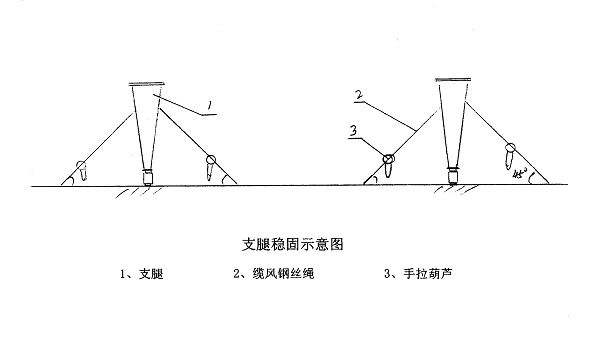

(5) lifting of legs

The supporting legs of the gantry crane work in an inclined position.Its hoisting state is also inclined, compared with the vertical hoisting, the hook and accurate alignment of the difficulty is greater.The method of rotation and sliding can be selected to lift the more ideal.

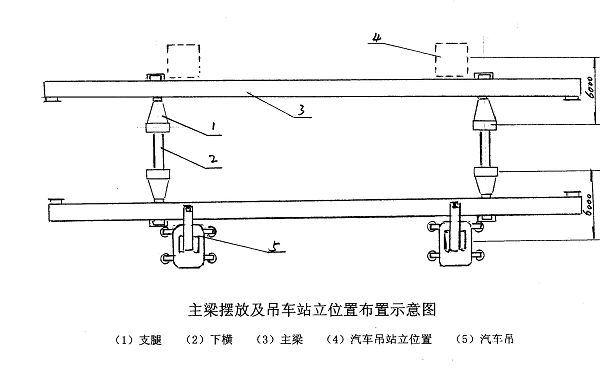

(6) main beam hoisting

(6) main beam hoisting

According to the actual measurement of the site, the fixed positions of the two auto cranes are worked out according to the required working radius of the auto cranes. The two main girders may be close to the ground girders to avoid the increase of the working radius of the auto cranes when the main girders are in place (see the figure).

(7) lifting by trolley

(7) lifting by trolley

(8) installation of driver's cab

(8) installation of driver's cab

V. electrical installation of Weihua crane gantry cranes

(1) installation of electrical equipment

After the installation and erection of the crane, it can be used

for the installation of electrical equipment, laying of wires and pipes, wiring

and safety grounding, etc.

Before installation, you should be familiar with the electrical

schematic diagram, wiring diagram, general electrical drawing and relevant

technical documents in detail, understand the operation principle and the role

of each component, so as to accurately install and quickly deal with the

problems in the installation process.At the same time, due to transport,

storage may cause damage to electrical equipment, so before the installation of

electrical equipment should be some necessary inspection.

First of all, clean, check the appearance and observe whether

the action of the active part is flexible, such as damage, loose or stuck

phenomenon, should be eliminated.

Check the motor, solenoid, contactor, relays, resistors and

other electrical components of the insulation performance, by measuring the

insulation resistance by megger, Ω, such as less than 0.5 M should be dry

processing, after inspection, to install and use.

Check the pressure between the carbon brush and the slip ring of

the motor, and whether the pressure between the controller, contactor and relay

contacts conforms to their respective regulations. If the pressure is too high

or too low, it should be adjusted.

Check the internal wiring of the control room, control panel

(box) and electrical components, and eliminate any loose or falling off.

Install all electrical equipment and components as shown in the

general electrical drawing or other installation drawings.

(2) adjustment of electrical equipment

Load test for gantry crane installation of Weihua crane

(1) no-load test

Turn the brake wheels of each mechanism by hand, so that the

last shaft (such as the wheel shaft or drum shaft) should not be stuck when

rotating for one week.Then start the motors of each mechanism separately. The

mechanism should operate normally and the limit switch should work

reliably.When the car is running, the driving wheel should be in contact with

the whole length of the track.

(2) static load test

The purpose of static load test is to test the carrying capacity

of each component and metal structure of crane.

Lift rated load (can be gradually increased to rated load),

running back and forth on the full length of the bridge, check the performance

of the crane should meet the design requirements, discharge the load, make the

car parked in the middle of the bridge, set the benchmark point of measurement,

general types of cranes, should gradually lift 1.25 times the rated load;For

cranes with special requirements, they can gradually lift 1.4 times of the

rated load off the ground by 100~200mm and suspend for at least 10min, then

unload the load and check whether the bridge has permanent deformation.Drive

the trolley to the cross-end to check that the actual arch value should not be

less than (0.7/1000) S.

After the static load test, all parts of the crane shall not

have cracks, loose or damaged connections, or other quality problems affecting

performance and safety.

(3) dynamic load test

The purpose of dynamic load test is to check the working

performance of each mechanism of crane and its brake.Test lifting 1.1 times

rated load.(if required, the test load can be determined according to the

lifting weight. The light, medium and heavy working types of Gn less than or

equal to 50t and the lifting weight Gn>50t of all working types of the crane

should be lifted 1.1 times of the rated load;Lifting weight Gn 50t working type

crane should lift 1.2 times rated load for dynamic load test.During the test,

the lifting mechanism shall be started at the same time, and repeated starting,

running, stopping, forward turning, reverse and other actions shall be

continued for at least 1h according to the cycle time specified by the type of

work.All kinds of mechanism should act sensitively, work balance is reliable,

all sorts of limit switch, safe device work is accurate and reliable.

All parts shall be seamless wear and other phenomena, the joint

shall not be loose.

Crane installation completed for inspection

After the crane is installed and self-checked, the inspection

report shall be submitted to the crane user. The crane user shall make

necessary review and review on the installation quality of the crane and the

performance quality of the crane after installation.After the crane is checked

and accepted, all technical documents shall be signed by the representatives of

both parties and accepted and handed over.

Viii. Quality assurance measures for crane installation

1. Establish and improve the construction management system

1) strictly carry out the construction system of the blue

prints.the design, construction site technical disclosure system, elaborate

organization, careful construction, work with quality to ensure product

quality, from raw materials, equipment and material into the factory began to

control, the key positions and key working procedure must be strictly

controlled, in strict accordance with construction drawings, specifications,

standards, and construction of technical documents;

2) special types of construction personnel must hold a

certificate;

3) strictly implement the quality "three inspection

system", that is, self-inspection, mutual inspection and special

inspection, fill in the inspection records carefully, and sign for confirmation

for archiving. For concealed works, they must be checked and confirmed to be

qualified by the on-site guidance personnel, supervision department and special

inspection personnel of the equipment manufacturer, and make records before

moving to the next construction procedure.

4) strengthen the technical file arrangement and filing system,

and make sure that the project materials are clear after completion.

For more information on overhead crane installation, please email info@hnwhcrane.net ,Thank you