Product Categories

Hot Products

-

Product Name: Electric Flat...

-

Product Name: Lifting...

-

Product Name: Type A 5t-800t double-beam...

-

Product Name: Gantry Crane for Railway...

-

Product Name: FEM/DIN Double Girder...

News

1. Domestic first-class large enterprise groups

Weihua crane is vice President of China heavy machinery industry association unit, China heavy machinery industry association bridge crane branch vice President of units, China material handling machinery association vice President of units, the national quality management advanced enterprise, national lifting industry volume has the biggest and strongest brand, one of the most competitive enterprise groups,Have "academician workstation" and "post-doctoral scientific research workstation", "enterprise technology centers recognized by the state", "provincial hoisting machinery equipment engineering technology research center", "national recognition technology inspection and test center" and "national professional skill appraisal" of the high-tech enterprises, as well as the "good faith typical demonstration enterprise in China".

"Wei hua" brand hoisting machinery has won the "Chinese famous brand products", "China well-known trademark" title, Weihua crane has been rated as "national technology innovation demonstration enterprise", "national quality standard", "national torch plan key high-tech", "high-tech enterprise", "national integrity of law-abiding enterprises", "the contract heavy credit enterprise", "China machinery industry top", "provincial quality prize".

Weihua crane set up 29 years, always maintained a rapid development speed, especially in 15, "11th five-year plan" period, but also achieved great development by leaps and bounds, the operation indexes average annual growth rate over 60%, from 2006 to 2015, Weihua crane, bridge, gantry crane production volume in the industry first, the national second electric hoist production volume.The products are widely used in machinery manufacturing, iron and steel metallurgy, nuclear energy industry, aerospace military industry, mining, water conservancy and hydropower, highway and railway, power energy, automobile manufacturing, petrochemical, port logistics, shipbuilding and other material handling fields.The products sell well all over the country, some products are exported to Britain, Russia, Turkey, Brazil, Vietnam, Thailand, India, Iran, Pakistan, Oman and other countries and regions.

2. Perfect quality management system and strong quality management team

Weihua crane established and improved the company's quality management system according to the "ISO 9001 international quality management system" standard.Adhere to the quality system of internal and external audit, the quality management work into the enterprise production and operation of the whole process.Since 1999, the company has been the first to pass the ISO9001 international quality management system, ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification in the same industry in the region, and has passed the acceptance inspection in subsequent years.

In order to support the construction of national defense, Weihua crane adjusted the strategic policy of serving the military industry in a timely manner, established the ministry of military industry, and cooperated closely with related units in the fields of national defense construction, aerospace, and nuclear construction to establish a complete set of quality assurance system for the military industry.Weihua crane was the first to obtain the national military standard quality system certification in 2013, and was successfully certified again in the re-certification process in May 2016.

There is a sound product quality assurance system, a sound quality inspection institutions and quality inspection personnel, from the development of the production process, the implementation of the product inspection system, supervision and inspection to the production and management of the workpiece are under control, Weihua crane has the national recognized product testing and inspection center.Established product testing center, chemical analysis center, physical performance testing center, measurement testing center and other departments.And equipped with "intelligent vibration aging instrument", "microcomputer digital display manganese phosphorus silicon analyzer", "high frequency infrared carbon and sulfur analyzer", "impact, stretch, hardness testing machine" X-ray, ultrasound, magnetic powder and other non-destructive inspection and metallographic analysis, such as excellent performance, fully functional testing equipment.And the establishment of domestic first-class crane electrical testing, simulation control room.

Weihua crane is also equipped with a variety of corresponding quality inspection equipment.Equipped with to meet the requirements of various specifications of weld inspection instruments, test the brinell hardness, rockwell hardness tester, a portable hardness tester, testing frame arch bridge and wheel level high and low level of poor, theodolite, check the gear machining accuracy of gears comprehensive performance tester and electric hoist and crane performance test rig and a variety of special testing tools, etc.

Weihua crane vigorously strengthened the construction of the quality inspection team, the company's quality inspection team of professional staff reached more than 100 people, 10 of them have obtained the quality engineer qualification certificate.Quality inspection personnel are distributed in all links of production, and the product is subject to the inspection system of "three inspections", the processing technology is strictly implemented, and the "one-vote rejection of product quality" system is strictly implemented.The establishment of a sound product quality file, with a dedicated management.

3. Strong technical strength

3.1 advanced technology: the latest design drawings are adopted. Weihua crane always puts advanced technology in the first place in product design: for example, ANSYS finite element method is used to analyze and calculate the section of the main beam to ensure that it has enough strength, stiffness and overall stability.Use Pro/E and other advanced software to analyze the structure of the system, and related secondary technology development, new product performance optimization design.The tender of all product design are also used with the latest international standards in line with the latest national standards (such as all the latest national standard gb3811-2008 crane design specifications, representing the latest level of domestic products.

3.2 strong technical strength

Weihua crane has more than 600 technical personnel, including 2 academicians, 6 foreign experts, 2 experts enjoying the state council allowance, 5 senior engineers, 25 senior engineers, 7 postdoctors, 15 doctors, 123 masters, 461 engineers, is the industry's largest technology research and development team.At present, Weihua crane has been recognized as "enterprise technology research and development center" and "post-doctoral research station" by the state.

Thousands of front-line production employees have become an experienced and skilled production backbone force of Weihua after more than 20 years of production practice, perennial technical training, technical competition and other means of training, Weihua crane has a national "employee skill appraisal center.

3.3 complete processing technology and mechanism

Weihua crane, in order to ensure the processing quality of products, establish a complete set of technology system, the process of establishment and management of centrally responsible, process of 40 existing engineering and technical personnel, and equipped with full-time on-site process management, especially for special processes, such as welding, heat treatment, etc., from the ability to mount guard personnel qualifications, equipment, process to the process parameters of track monitoring are put forward clear requirements, to ensure the quality of the special process stability.

Weihua crane has developed nearly 20 process codes, more than 10 general technical conditions and operation instruction CARDS for each process, fully ensuring the production quality of products to meet the requirements of the drawing design.

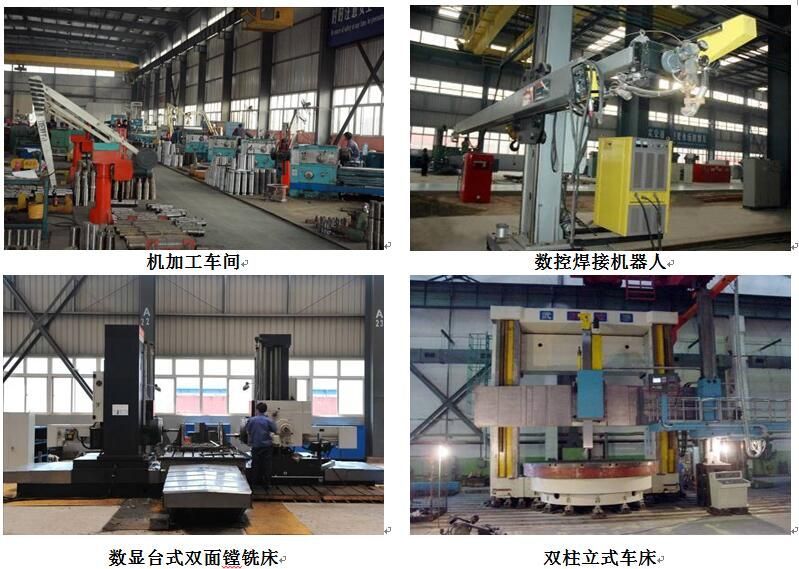

3.4 advanced equipment

Weihua crane is equipped with complete equipment to meet the requirements of crane process.In recent years, the company increase investment in technological upgrading, the total investment of more than 200 million yuan, has acquired in large CNC floor-type milling and boring machine, CNC cutting machine, "the mode of welding roller machine", "digital hydraulic sheet metal bending machine", "very large CNC horizontal lathe", "digital display plane desktop double-sided boring", processing module of m32 gear hobbing machine, rolling steel plate thickness 105 mm "numerical control hydraulic level of three-roller plate type", processing 5 meters in diameter "large double column vertical lathe," and "CNC machining center, etc.;It has the first "shot blasting paint drying line", "gourd paint drying line" and the largest "100T gourd test bench and test center" and other advanced processing equipment for single beam production.

It has a steel structure production workshop of 60,000 square meters, which can be called the first in the world.In addition, a variety of professional plant area of nearly 80,000 square meters.

From raw materials into the factory to the final machine factory are equipped with the corresponding modern production equipment.Such as:

A. steel plate pretreatment

Weihua crane has three steel plate pretreatment production lines. After the steel plate enters the plant, it firstly carries out shot blasting and rust removal on the steel plate, and after rust removal, the primer is sprayed on the steel plate.Ensure the quality of steel plate is in accordance with the specification before production.

B, trolley frame overall processing

Weihua crane has TX6920 floor boring and milling machine and other super-large equipment, its working stroke: 16 meters long, 5 meters high, 2 meters deep,

Can carry on the crane extremely large parts the whole processing.For example, the production of the trolley frame, motor, reducer and other base and running platform support are all welded on the trolley frame after the line and then in TX6920 floor boring and milling machine for overall processing.It can ensure the relative positions of the main and auxiliary lifting mechanism and the trolley running mechanism on the trolley frame, and the matching precision can meet the design requirements.Especially for the solution of the large tonnage of the overall processing of the trolley frame more shows its unique advantages.

C, large drum processing

Weihua crane has CK61315 x 8/40 large heavy lathe numerical control processing, the domestic industry, a big, heavy internal security China only), machinable 3.15 meters in diameter, length, up to 8 meters, unit weight of 40 tons of oversize artifacts (e.g., large tonnage of hoisting drum), Weihua crane, also has the x2500 W11SNC - 105 three-roller plate can be rolled 105 mm thickness of steel plate into a round shape, make my company become a domestic large tonnage of hoisting drum within the industry one of the few manufacturers.In order to ensure the quality of the welding drum, Weihua crane has built a 4 4 12m annealing furnace, which can carry out effective annealing heat treatment after the whole welding of the drum (including the trolley frame after the whole welding), which can fully remove the internal stress after the whole welding of the drum (including the trolley frame) and ensure the quality of the whole processing of the drum.

D. high-precision CNC cutting machine

Weihua crane has 2 sets of messel large CNC cutting machines, the equipment is the product of the German messel cutting equipment manufacturing company, for the world's first-class CNC cutting equipment, but also the domestic industry in the number of manufacturers have some high, fine, sharp cutting equipment.Messel cutting equipment is used to process all kinds of complex workpieces of lifting equipment, such as the arch curve of the web of the main girder, the board lifting hook of large tonnage and the large divider in the main girder.The accuracy of component size and geometry is guaranteed, and the appearance of component is also guaranteed.

E. Fully functional welding equipment and heat treatment equipment

Weihua crane has nearly 500 sets of the most advanced and ideal types of submerged arc welding machines, CO2 gas shielded welding machines, as well as first-class heat treatment equipment for various crane parts to meet the requirements of heat treatment of products, providing reliable guarantee for the production of high-quality crane products.

3.5 complete inspection means and advanced science

Weihua crane has a sound product quality assurance system, a sound quality inspection institution and quality inspection personnel, professional quality inspection personnel up to more than 100 people, from the provisions of the production process, verification, implementation, supervision and inspection to the production and management of the workpiece are under control, and equipped with a variety of corresponding quality inspection tools.

Weihua crane has the national certification product inspection center.Physical and chemical analysis room and physical performance test room for material inspection, X-ray inspection room and ultrasonic filter inspection room for inspection of weld quality, crane electrical test room and simulation control room, etc.Equipped with to meet the requirements of various specifications of weld inspection rule, test the brinell hardness, rockwell hardness tester, a portable hardness tester, testing bridge rack wheel camber, level of high and low level of poor, check the gear machining accuracy of gears comprehensive performance tester and electric hoist and crane performance test rig and a variety of special inspection tools.

3.6 adopt parts and accessory products of advanced or famous brand factories

Weihua crane's supporting products are all through the inspection and acceptance of the product quality of the supporting plant, to ensure that the product quality of the supporting plant is first-class, and represents the current advanced level at home and abroad, or the products of the famous brand plant.For example, the steel suppliers are famous large domestic steel enterprises products;The motor fitting factory is selected from more than ten production plants.Electrical appliances, brakes and reducers of the factory is a large professional domestic manufacturers.As a long-term strategic partner of our company, these accessory factories constantly listen to and improve our requirements and users' requirements on product quality, which is an important aspect to ensure the continuous improvement of our product quality.

3.7 advantages of product development and design

It is capable of producing general bridge and gantry cranes with lifting capacity of 900t and below, and has strong market competitiveness. It has designed and manufactured lifting equipment with high technical content and strong professionalism for many industries, and many products have been greatly improved, optimized and innovated on the original design standard.

Weihua crane has provided lifting equipment to various customers at home and abroad, including: large tonnage bridge crane with lifting weight up to 800t;5-300t low clearance, low wheel pressure bridge crane;All kinds of electromagnetic chuck crane with the function of topspin or downspin;50-100t slab clamping crane;100-320t metallurgical bridge crane;Full frequency conversion bridge crane for workshop of 80-250t power station;Garbage incineration power plant crane with remote control and full program operation;Gantry crane for shipbuilding with lifting weight up to 800t, long span, high lifting capacity and hull turning function;Super-high hoist 400m tunnel portal crane;440t full frequency conversion shield gantry crane and other rail or tire container gantry cranes;Portal crane;900t bridge erector and beam shifting machine;All kinds of hydraulic machinery: lifting and closing machine, dam top door machine, sewage gate, etc.China's first full intelligent tank impact test platform and satellite launch center capsule drop test device, etc., in which ND series electric hoist, HD electric single beam in the domestic leading level, fully reflects the product development and manufacturing capacity of Weihua crane.

3.8 technological innovation advantages

Technological innovation is the soul of an enterprise and the driving force of its development.Weihua crane established "Weihua design and research institute" on the basis of introducing and training technical personnel. At the same time, it prepared wuhan and Shanghai branches to be responsible for the development and design of new products.Inside: mechanical analysis room, new product development room, basic parts research room, port machine room, bridge machine room, door machine room, etc.In recent years, among the products and technologies developed under the charge of weihua design and research institute, 498 national patent certificates have been applied, among which 43 invention patents have 10 new technological achievements that have passed the national and provincial appraisal, 1 international advanced level and 9 domestic advanced level.Among them, the 40-ton gantry crane with the lifting height of 400 meters is the most gantry crane with the lifting height in the industry at present, and has been used in the construction of the hydropower station with pumped storage for the supporting project of the Olympic Games, making its due contribution to the smooth holding of the 2008 Olympic Games.The 200+200t class shipbuilding gantry crane developed by ourselves makes weihua step into the field of large shipbuilding cranes successfully.Self-designed and manufactured variable frequency speed control, PLC control of the 600 tons of bridge crane, henan province to fill the design, manufacture of super-large cranes and so on.The independently designed wheeled container crane and rail container crane mark a solid step for Weihua crane from the former bridge gantry crane to the new field of port and container crane in terms of technical strength, technological level and manufacturing capacity.The "GLQ40 dual-drive ac frequency converter port tire crane" developed by Weihua crane won the third prize of China machinery industry science and technology award in 2009.Previously, the project was included in the 2008-2009 national torch program.Dual-drive ac frequency conversion port tire crane adopts dual-drive ac frequency conversion technology, which can be driven by the public ac power grid and can also work with its own diesel engine. Where there is an external public power grid, it avoids the environmental pollution caused by the combustion of diesel and saves the energy cost during operation.This crane through the PLC programming control system will be electric tire crane speed performance, protection performance, reliable performance to a new height.At the same time, the failure rate is reduced to the lowest level, reaching the leading level of tire crane technology.Products by henan institute of science and technology international scope of science and technology innovation, is the first at home and abroad.

Take the lead in the research and development of anti-sway technology of crane: Weihua crane has started the research on anti-sway technology of crane since 2006, and the research and development team led by doctor, through nearly 8 years of research and test, has achieved remarkable results, and now has obtained the patent and has been widely used.The patent is advanced and practical, and is in the leading position in the world.On November 3, 2016, China's new generation of large carrier rocket "long March 5" was successfully launched at hainan wenchang space launch base.The anti-sway crane independently developed by weihua has completed the handling, turning, testing and testing of "long march no. 7" in the workshop with high precision, demonstrating the strong technical strength of the group.The technology has served the four major satellite launch centers and other major national space projects, and successfully assisted the "tenth shenzhou-10", "eleventh shenzhou-11", "chang 'e-3", "tiangong-1" and "tiangong-2" flights.