Product Categories

Hot Products

-

Product Name: Electric Flat...

-

Product Name: Lifting...

-

Product Name: Type A 5t-800t double-beam...

-

Product Name: Gantry Crane for Railway...

-

Product Name: FEM/DIN Double Girder...

Project Case

Working system of weihua crane (relationship between load state, lifting weight and working level of crane)

(For crane selection and quotation, please email to info@hnwhcrane.net, thanks.)

Years of crane manufacturing and crane safety management work make us weihua crane found that some workers in the lifting equipment "three at the same time" review confused the crane load state, lifting weight and working level is one thing, that is, the higher the working level, the higher the load state;The lower the working level, the lower the load state;Or the crane rated load is bigger, the work level is higher;The lower the rated load of crane, the lower the working level.The main reason for this error is that the concept of working level, load state and load capacity of the crane is not clear.In the "three at the same time" when the audit often caused errors.First, the "big belt and small belt" has wasted funds; second, the "small belt and big belt" has buried the hidden danger of accidents.In order to attract people's attention, master the relationship between them, and facilitate our application in production practice, the following three parts are discussed:

Years of crane manufacturing and crane safety management work make us weihua crane found that some workers in the lifting equipment "three at the same time" review confused the crane load state, lifting weight and working level is one thing, that is, the higher the working level, the higher the load state;The lower the working level, the lower the load state;Or the crane rated load is bigger, the work level is higher;The lower the rated load of crane, the lower the working level.The main reason for this error is that the concept of working level, load state and load capacity of the crane is not clear.In the "three at the same time" when the audit often caused errors.First, the "big belt and small belt" has wasted funds; second, the "small belt and big belt" has buried the hidden danger of accidents.In order to attract people's attention, master the relationship between them, and facilitate our application in production practice, the following three parts are discussed:

I.

expound relevant concepts

1.

Rated load G

Refers

to the maximum allowable lifting momentum (including the weight of separable

spars) of a crane in normal operation, expressed in tons (t).

2.

Load state Q

It

is a parameter reflecting the change of crane load and the change of load

action times.It is usually expressed as the

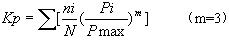

nominal load spectral coefficient Kp.Kp is expressed

by the ratio of the actual lifting load Pi to the maximum lifting load Pmax and

the number of lifting loads ni to the total number of working cycles N, and the

formula is:

According to the nominal load spectrum system Kp size is divided into four levels of Q1 light - Q4 heavy.

3. Utilization level

It

reflects the frequency of crane design life cycle.Denoted by the total number of

working cycles N, it is successively divided into 10 levels of u0-u9 from small

to large

U0-u3 cranes are not often used

U4

cranes are often used sparingly

U5

cranes are often used in moderate conditions

U6

cranes are often used busily

U7-u9

cranes are in heavy use

4. Work level A

It

reflects the working characteristics of crane in load condition and utilization

busy degree.

The division of working level is determined by the utilization grade U and load state Q of the crane.They are divided into eight levels, A1 ~ A8.

The working level of the crane, that is, the working level of the metal structure, according to the lifting mechanism, divided into a1-a8, if compared with the crane work type stipulated in China, roughly equivalent: a1-a4-light;A5 - A6 -;A7- heavy, A8- extra heavy.

Second, correctly recognize the differences between them

Load

state Q1 light -Q4 heavy refers to the crane in the lifting weight full load

degree change, although can work in full load, but the degree of full load is

not the same, such as some frequent full load;Some

are often fully loaded;Some are occasionally full.The safety coefficient that USES when designing manufacturing

so is different, with makings and structural respect have strict divisional,

and price change is bigger also.

Working

level is a comprehensive reflection of the crane in the working time of the

busy degree and lifting weight of the full load of the characteristics.It can be seen that when the working level is low, it may be

an extra-heavy crane, while when the working level is high, it may be a light

crane. It cannot be considered that the working level is high and the working

level is low and light.

Working

level is a comprehensive reflection of the crane in the working time of the

busy degree and lifting weight of the full load of the characteristics.It can be seen that when the working level is low, it may be

an extra-heavy crane, while when the working level is high, it may be a light

crane. It cannot be considered that the working level is high and the working

level is low and light.

In

addition, the level of crane work, does not depend on the size of the lifting

weight, but depends on the lifting weight load and load frequency changes and

engineering busy degree changes.

Three,

strict "three at the same time", the correct choice of crane

"Labor

law" and "safe production law" have strict regulation to

establishment of safe and wholesome labor, namely the establishment of safe and

wholesome labor that builds, rebuild, expand a project must be designed with

main body project at the same time, at the same time construction, put into

production and use at the same time.As the author of Ann mechanic only master the relevant national

standards and professional knowledge, in order to better grasp the "three

at the same time" the right to review.

It

can be seen from the table of "classification of crane working level"

that the load state has four grades.Busy degree has

8 grades, crane type is more.So which is the

best choice?Let's illustrate the use of

this table with two examples.

According to the working condition of the crane, that is, the working frequency is very low, the lifting work is generally in the state of full load, should choose the working level of A1 ~ A3 type crane is more appropriate, in the performance can meet the requirements, in the price is more economical.

If the crane of working level A7 ~ A8 is selected according to its lifting weight, it will waste a lot of money.

Case 2.What type of crane should be selected for weihua crane 5t Overhead crane (EOT crane) frequently used in the warehouse of a foreign trade company?

According to the working condition of the crane, that is, the working frequency is high, lifting load is generally in the state of medium load, should choose the working level in A6 ~ A7 crane is more appropriate, although the price is higher, but can complete frequent work.If the crane of A1 ~ A3 type is selected according to the lifting weight, although it can be used, it may often break down, its service life is short, and it cannot complete the busy work every day.

Attachment: example of working level of

weihua crane

Attachment: example of working level of

weihua crane

|

Crane type |

Work level |

||

|

overhead crane(EOT crane) |

Hook type |

Installation and maintenance of power station |

A1~A3 |

|

For workshop and warehouse |

A3~A5 |

||

|

Heavy duty workshop and warehouse use |

A6、A7 |

||

|

clamshell |

Intermittent service |

A6 |

|

|

Continuous service |

A6~A8 |

||

|

Special metallurgy |

Hanging container with |

A7、A8 |

|

|

Charging with |

A8 |

||

|

foundry |

A6~A8 |

||

|

forging |

A7、A8 |

||

|

Quenching with |

A7、A8 |

||

|

For clamping and stripping |

A8 |

||

|

Peel with |

A7、A8 |

||

|

Material rake |

A8 |

||

|

Electromagnet type |

A6~A8 |

||

|

Gantry crane |

General purpose hook type |

A3~A6 |

|

|

Grab type for loading and unloading |

A6~A8 |

||

|

Hook type for power station |

A2、A3 |

||

|

Hook type for shipbuilding installation |

A3~A5 |

||

|

Container handling |

A5~A8 |

||

|

Gantry crane for loading and unloading bridge |

Grab type for loading and unloading |

A7、A8 |

|

|

Grab type for port handling |

A8 |

||

|

For loading and unloading containers at ports |

A6~A8 |

||

For crane selection and quotation, please email to info@hnwhcrane.net, thanks.